What is the Reasonable Cost for a Plastic Injection Mold?

Plastic injection molding is a widely used manufacturing process for producing plastic parts with precision and efficiency. However, one of the primary concerns for businesses and manufacturers is understanding the cost associated with plastic injection molds. In this article, we will delve into the factors that determine the reasonable cost of a plastic injection mold. By exploring these factors, you will gain valuable insights into the pricing structure and be better equipped to make informed decisions.

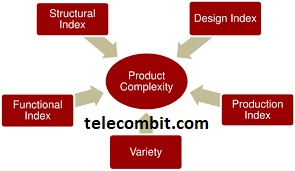

Complexity and Design Specifications

The complexity of the desired part design significantly affects the mold cost. Intricate designs with undercuts, complex geometries, or tight tolerances require more intricate molds and may involve additional processes like side actions or sliders. The more complex the design, the higher the cost.

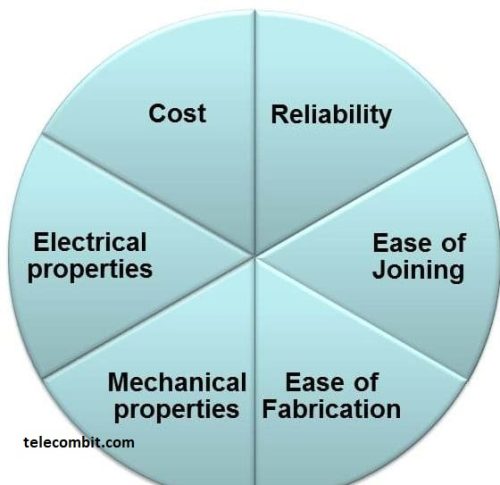

Material Selection

Different plastic materials have varying characteristics and requirements. Some materials, such as high-performance engineering resins, necessitate specialized molds that can withstand higher temperatures and pressures. These molds often incur higher costs compared to molds used for standard materials.

Dividend investing is a smart choice for investors due to its potential for passive income, long-term growth, lower risk, compounding benefits, inflation hedge, and overall stability in uncertain markets.

Mold Size and Complexity

The physical size and complexity of the mold impact its cost. Larger molds require more material, machining, and cooling time, leading to higher expenses. Additionally, molds with intricate features, multiple sliders, or unscrewing mechanisms involve additional manufacturing steps, contributing to increased costs.

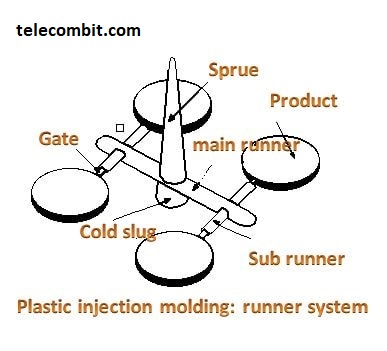

Mold Cavities and Production Volume

The number of mold cavities directly influences production volume. Molds with multiple cavities can produce more parts per cycle, reducing overall production time and cost per unit. However, molds with a higher number of cavities are more expensive upfront due to increased tooling and manufacturing complexity.

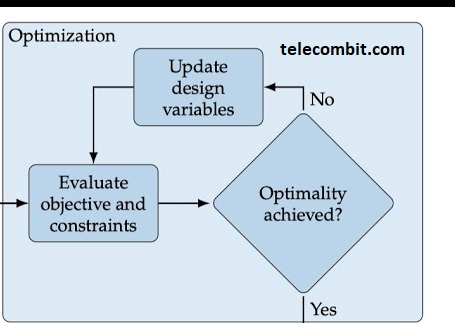

Cost Estimation and Quoting Process

To determine the cost of a plastic injection mold, manufacturers typically evaluate the project’s specifications, including part design, material selection, expected production volume, and surface finish requirements. Based on these factors, they provide a detailed quotation outlining the mold’s cost, production timeline, and any additional considerations.

Design Optimization

Collaborating with experienced designers and engineers during the product development stage can help optimize the design for manufacturability. By simplifying complex features, reducing undercuts, or adjusting tolerances, it is possible to minimize mold complexity and lower costs without compromising functionality.

Material Selection and Testing

Choosing the right material for your plastic part is crucial. Conduct material testing and validation to ensure the selected material meets the required specifications and performance standards. Opting for readily available and commonly used materials can help reduce material costs and minimize the need for specialized molds.

Collaboration with Experienced Manufacturers

Partnering with reputable and experienced mold manufacturers is essential. Their expertise and knowledge can guide you through the mold design process, recommend cost-saving measures, and ensure high-quality production. Requesting multiple quotes from different manufacturers and comparing their capabilities and prices can help make an informed decision.

Conclusion

Determining the reasonable cost for a plastic injection mold involves considering various factors, including complexity, design specifications, material selection, mold size, production volume, surface finish, tooling materials, additional features, geographic location, and manufacturer expertise. By understanding these factors and implementing strategies to optimize costs, businesses can make informed decisions, balance cost and quality considerations, and achieve successful plastic injection molding projects. In summary, the cost of a plastic injection mold is influenced by a combination of factors that must be carefully evaluated.