From Grove to Floor: The Journey of Wood Flooring

Wood flooring is not only a product; it is a story that begins in the heart of the woods and culminates in the warmth and elegance of a ruined floor. From Grove to Floor: The Journey of Wood Flooring. The journey of wood flooring involves numerous stages, each contributing to creating a timeless and cherished element in modern homes.

From bearable forestry practices to sophisticated manufacturing processes, let’s explore the fascinating journey of wood flooring, highlighting the care and craftsmanship applied in bringing nature’s beauty to our living rooms.

Endurable Forestry and Reliable Harvesting

The journey of wood flooring forms in well-managed forests where tolerable forestry practices are prioritized. From Grove to Floor: The Journey of Wood Flooring. Responsible harvesting ensures that only a fraction of mature trees are felled, letting the forest regenerate naturally.

Tree species are carefully chosen based on their growth rates and abundance, and local regulations and international guarantee, such as the Forest Stewardship Council (FSC), play a crucial role in promoting sustainable logging practices. By supporting responsible forestry, wood flooring works contribute to conserving forests, wildlife habitats, and overall ecosystem health.

Timber Extraction and Vehicle

Once the trees are carefully chosen and marked for harvesting, skilled loggers begin the process of timber extraction. Precision is vital to underestimate waste and prevent damage to encompassing vegetation. Once cut, the logs are transported to sawmills or processing facilities. From Grove to Floor: The Journey of Wood Flooring.

The transportation process often involves a combination of trucks and, in some circumstances, floating logs down rivers. This traditional method, known as log driving, is used in regions where channels offer a natural and efficient means of hauling timber.

Sawmilling and Drying

The logs are processed into rough timber at the sawmill through a series of cuts. This step involves removing the bark and shaping the logs into functional planks or boards. The freshly sawn wood possesses a high moisture content and needs to be dried to achieve the appropriate moisture level for flooring.

Kiln drying or air drying techniques reduce the wood’s moisture content and stabilize it for further processing. Proper drying is essential to prevent contortion, cracking, and other issues that could arise during the flooring’s lifespan.

Grading and Grade Control

After drying, the wood is carefully checked and graded based on its appearance, durability, and structural integrity. Wood flooring arrives in various grades, ranging from clear and even planks to character grades with distinctive knots and grain designs. Quality control measures guarantee that only the finest materials make it into the production line, holding the manufacturer’s reputation and ensuring customer happiness.

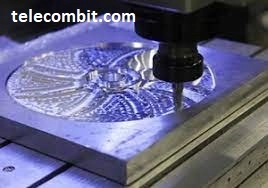

Milling and Profiling

Once the wood is graded, it experiences milling and profiling to create the desired proportions and edge profiles for the flooring. Tongue-and-groove profiling is common for wood flooring, allowing the planks to fit snugly together and deliver stability and strength to the finished floor. This precision milling is necessary to ensure a seamless and tight fit during building.

Spending and Surface Antidotes

Wood flooring can be left undone to showcase its natural beauty, but it often undergoes surface therapies to enhance its durability and build. Various finishes, such as oil, wax, or polyurethane, are applied to shield the wood from stains, moisture, and wear. Dyeing or brushing techniques may also add character and depth to the wood’s appearance, giving clients a wide range of choice to match their internal design selections.

Packaging and Diffusion

Once the wood flooring has been simulated and finished, it is carefully packaged and scheduled for distribution. The finished products are stacked and packed to prevent damage during transit. Wood flooring is distributed to retailers, building companies, and directly to customers, ready to be installed in homes, offices, and further spaces.

Building and Enjoyment

The final stage of the journey is the building of the wood flooring in the designated space. Skilled specialists ensure the planks are laid with exactness and care, creating a stunning and attractive floor. Once installed, the wood flooring adds warmth, dignity, and a touch of nature to the environment, converting a house into a home. With proper care and care, wood flooring can be enjoyed for decades, creating lasting recollections and connecting homeowners to the looks of the natural world.

Conclusion

The trip of wood flooring is a testament to the dedication and craftsmanship applied in bringing nature’s gift from the forest to our living spaces. From tolerable forestry rules to specific milling and finishing, each stage creates a durable, attractive, and timeless flooring choice. Assuming wood flooring is not just about counting elegance to our homes, it’s also a responsibility to support reliable environmental rules and cherish the artistry of timber in our everyday lives.